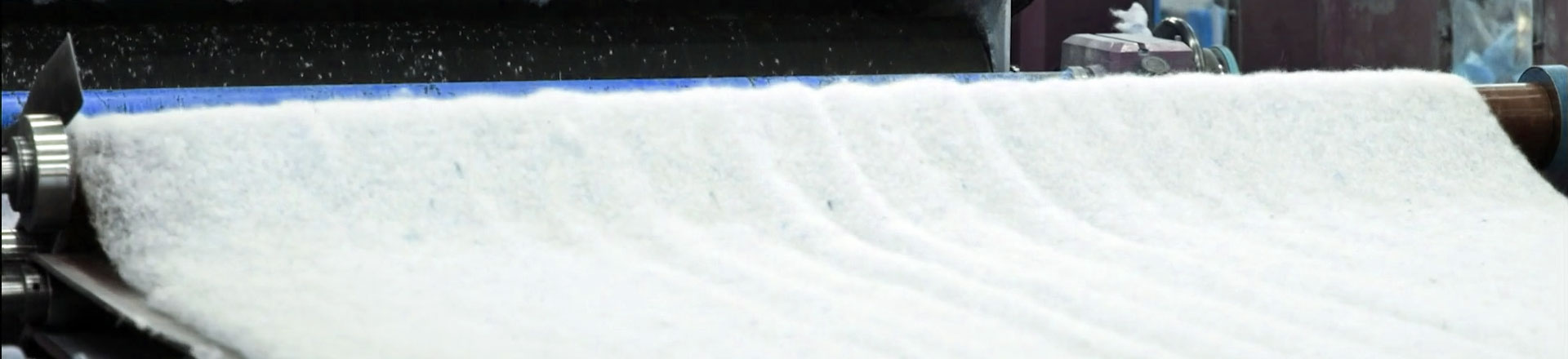

Liquid filter nonwoven products are essential in many industries, including food and beverage, pharmaceuticals, and manufacturing. They are designed to remove impurities, contaminants, and unwanted particles from liquids, making them safe and clean for use. The use of nonwoven materials in liquid filtration has many advantages over traditional methods, such as reduced maintenance costs, increased efficiency, and improved product quality.

One of the benefits of liquid filter nonwoven products is their high absorbency. These products can absorb liquids quickly and effectively, preventing contaminants from passing through the filter. They also have excellent retention properties, which means they can retain the filtered particles, preventing them from re-entering the liquid.

Nonwoven materials used in liquid filtration are also durable and can withstand harsh conditions, such as high temperatures and chemicals. This durability ensures that the filter can withstand repeated use and maintain its effectiveness over time.

Another advantage of liquid filter nonwoven products is their flexibility. These products can be customized to meet specific filtration requirements, such as the size, shape, and density of the filter. This customization ensures that the filter can adapt to a variety of liquids and effectively remove contaminants.

In conclusion, liquid filter nonwoven products are crucial in many industries, and their use is only increasing. These products offer many advantages over traditional filtration methods, including high absorbency, durability, and customization. As a result, many manufacturers are turning to nonwoven materials to improve the efficiency and quality of their liquid filtration processes. For those in the industry, it is essential to keep up with the latest advancements to ensure their products and processes are optimized for maximum efficiency and effectiveness.